Weight Testing.

Weighing is one of the most important processes in every pharmaceutical company. Every ingredient that is used for manufacturing a pharmaceutical product such as tablets and capsules must be weighed accurately so that the recipe - and finally the product quality - is not compromised. While weight checks are performed throughout all stages of the production process, weight testing at regular time intervals is essential for in-process control (IPC) during tablet compression or capsule filling. International Pharmacopeia include weighing as an integral part of different type of testing methods. Other chapters such as USP <41> and USP <1251> cover guidelines for the weighing equipment used and aim to ensure weighing accuracy - or state that the type and frequency of balance checks should be determined by the risk and process tolerance of the application.

WT50 –

Online Weighing.

With your Tablet Press.

Watch the Video

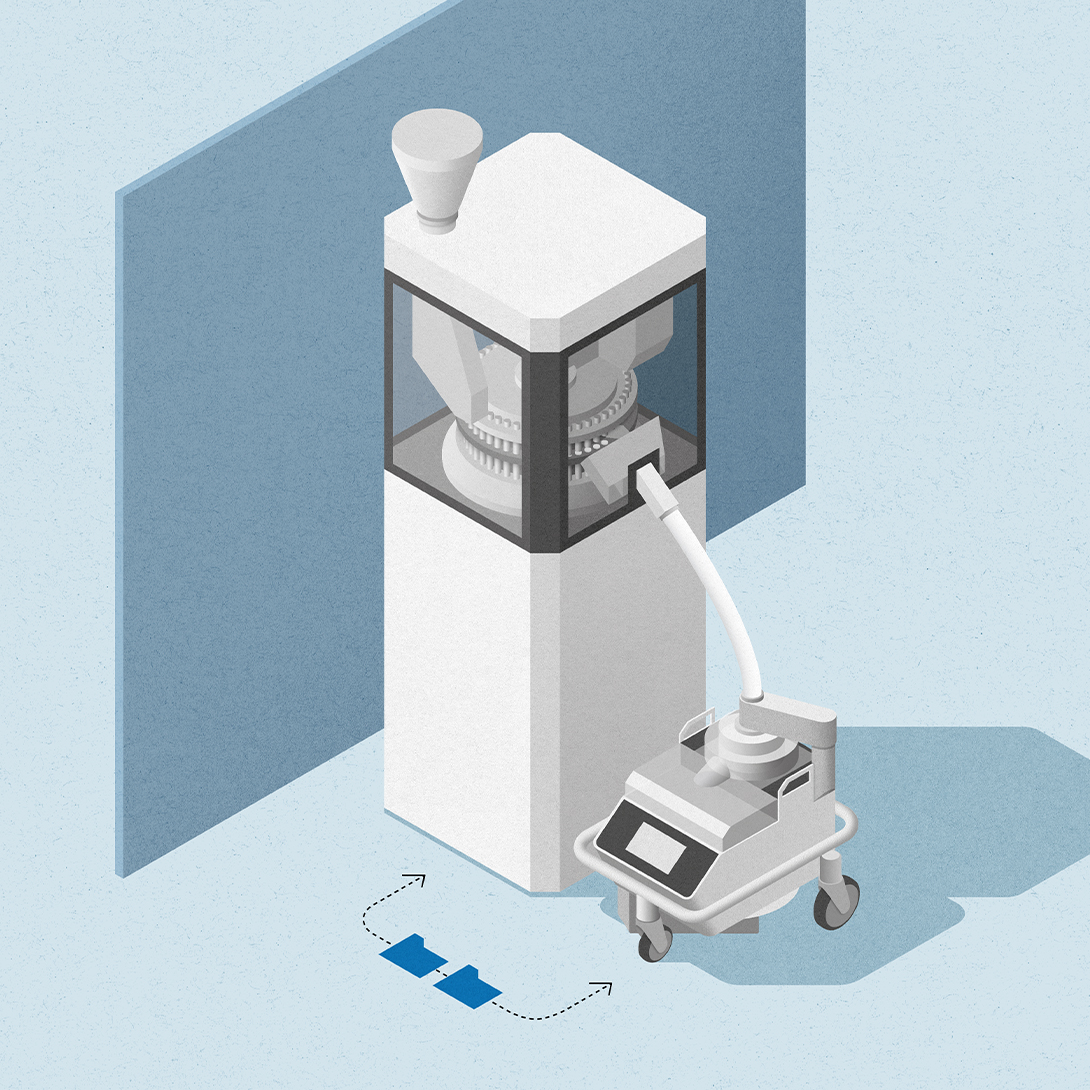

Prevent potential manufacturing problems caused by weight drift without any operator required to be present inside the compression room. The WT50 can be fully integrated with your tablet press for 100% unattended operation. Once a campaign has been started, samples are automatically diverted to the weight tester at regular time intervals. The WT50 reliably measures individual sample weights and transfers results to the tablet press for automated self-adjustment in real-time.

- ONLINE - Integration with different brands of tablet presses for automated self-adjustment

- COMPACT - Robust design with small footprint for minimum space requirements

- FEEDING - Low inlet height allows for gravity feeding by placing the tester directly below the sampling gate

- OPTIONS - Modular design allows to configure the tester for specific integration requirements

- ACCURATE - High-precision weighing module with elevated platform and programmable cleaning intervals

- CALIBRATION - User-guided adjustment & verification procedures with printed report

- MINIMUM WEIGHT - Automated determination of minimum weight (e.g. USP<41>) at place of installation

Integration Options

Highlights

Online Integration.

The WT50 can be seamlessly integrated with different brands of tablet presses. The compact weight tester only requires minimum floor space inside the compression room and can be connected with both single-side and double-sided tablet presses. Thanks to its low inlet height and modular design, the WT50 is perfectly suited for gravity feeding by placing the unit directly under the sampling gate of the press. Alternatively venturi-feeding allows to position the tester at a distance from the press.

Watch the Video

Simply Reliable.

The WT50 excels with fast and uncomplicated operation. A universal high-speed separator reliably feeds individual samples to the integrated high-precision weighing module and can easily handle different shapes & sizes without any adjustments. To prevent negative air pressure of the connected press influencing weight measurements, the test area of the WT50 is closed off during test execution using a sliding damper.

Accurate Weighing.

The vibration-resistant integration of a high-precision weighing module ensures fast & accurate measurements in the demanding environment of a compression room. Common problems known from conventional online weighing systems such as erroneous measurements caused by tablet debris or broken pieces are prevented by the unique elevated weighing platform design with integrated cleaning function.

Collect Samples.

In addition to performing unattended weight tests at regular intervals, the WT50 can also collect samples for further testing in the lab or for future reference. The space-saving sample collector is located underneath the tester and doesn't increase the overall footprint. Different collection modes for double-sided presses and bulk collection are readily available.

Minimum Weight.

The WT50 features an automated built-in procedure to determine the system's minimum weight at the place of installation. The accuracy of the weighing module is assessed according to USP <41> and the minimum weight is automatically calculated. A detailed minimum weight report can either be printed or transferred to an USB flash drive without requiring any additional software.

Watch the Video